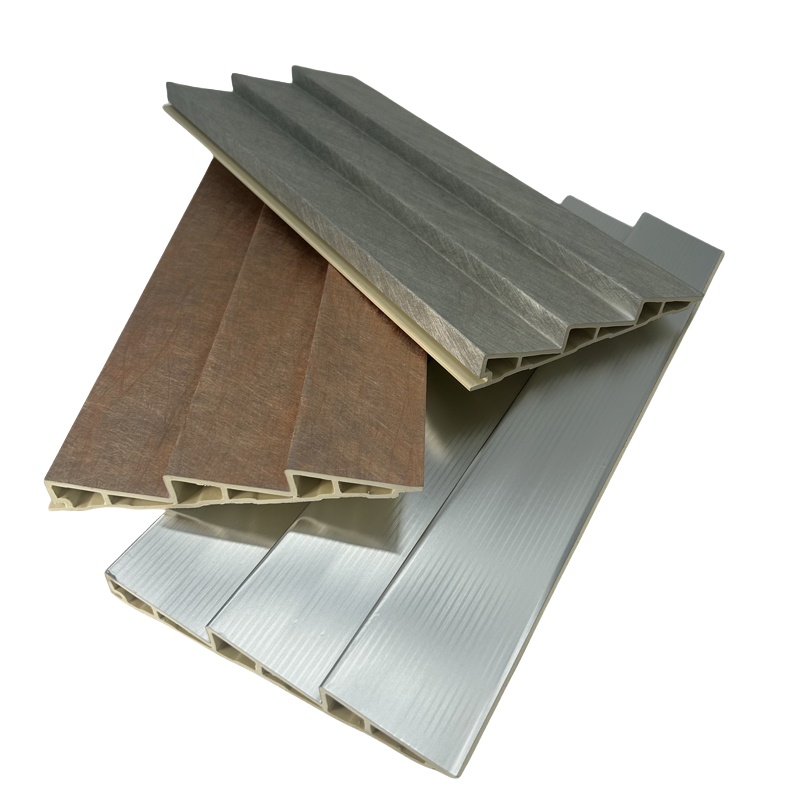

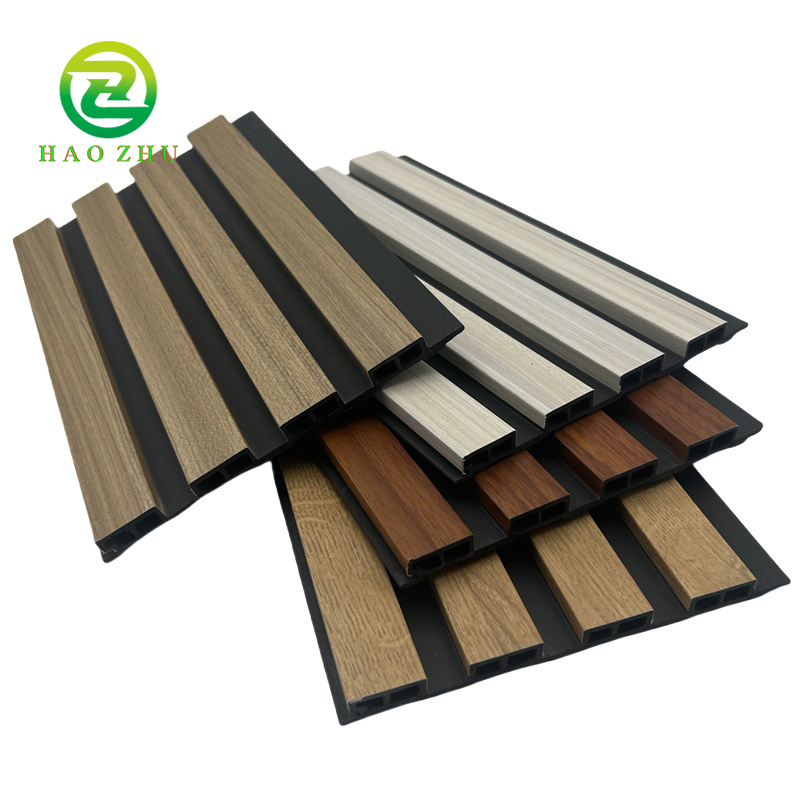

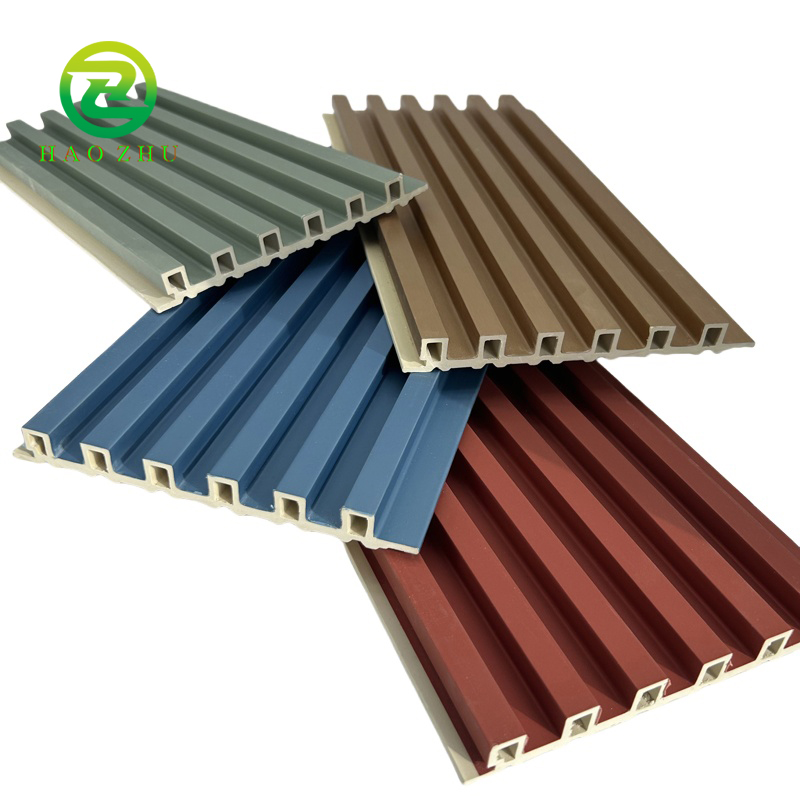

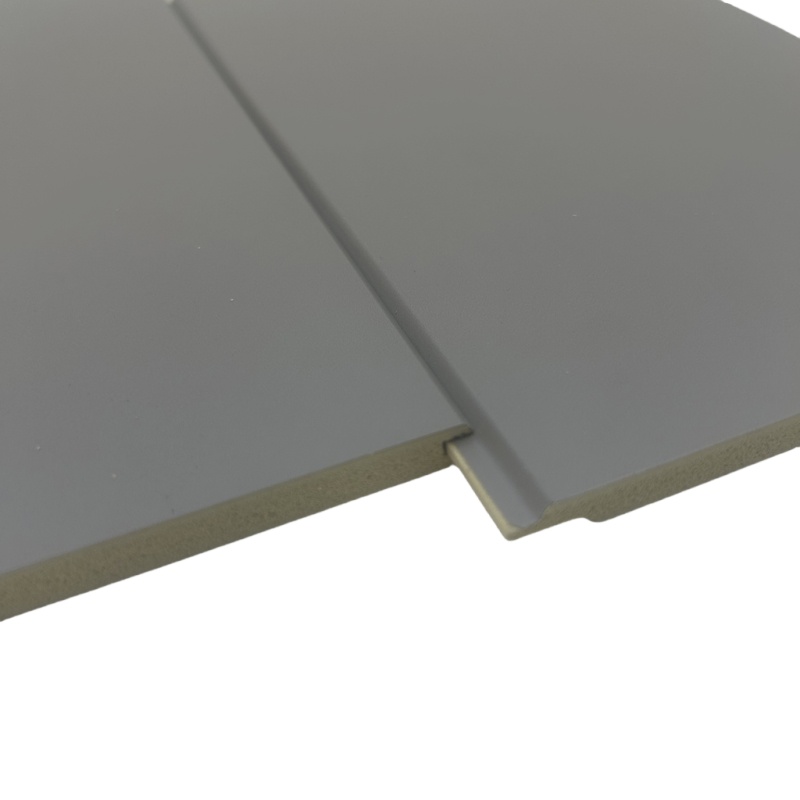

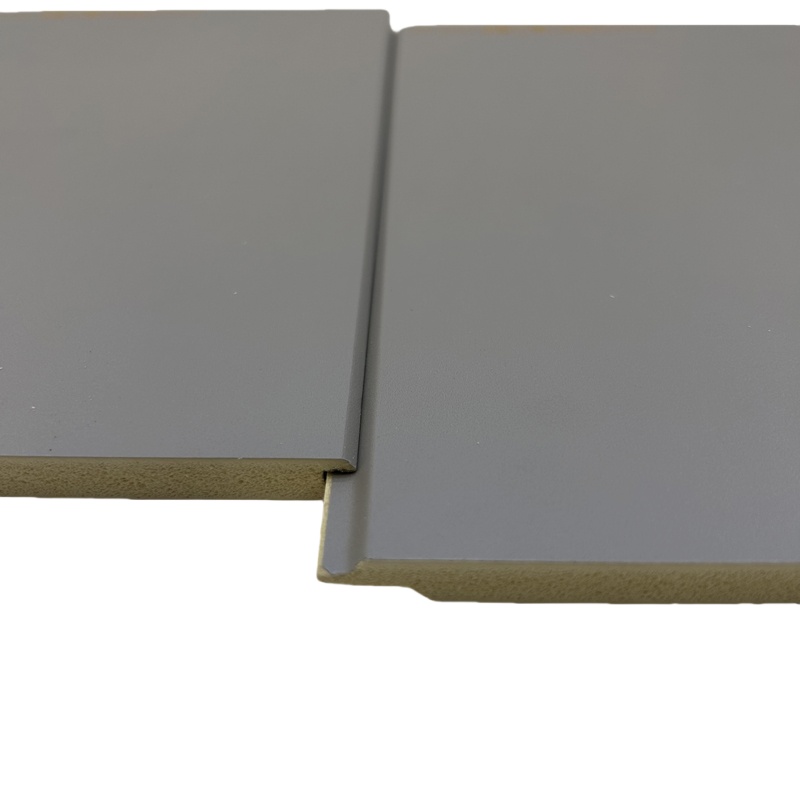

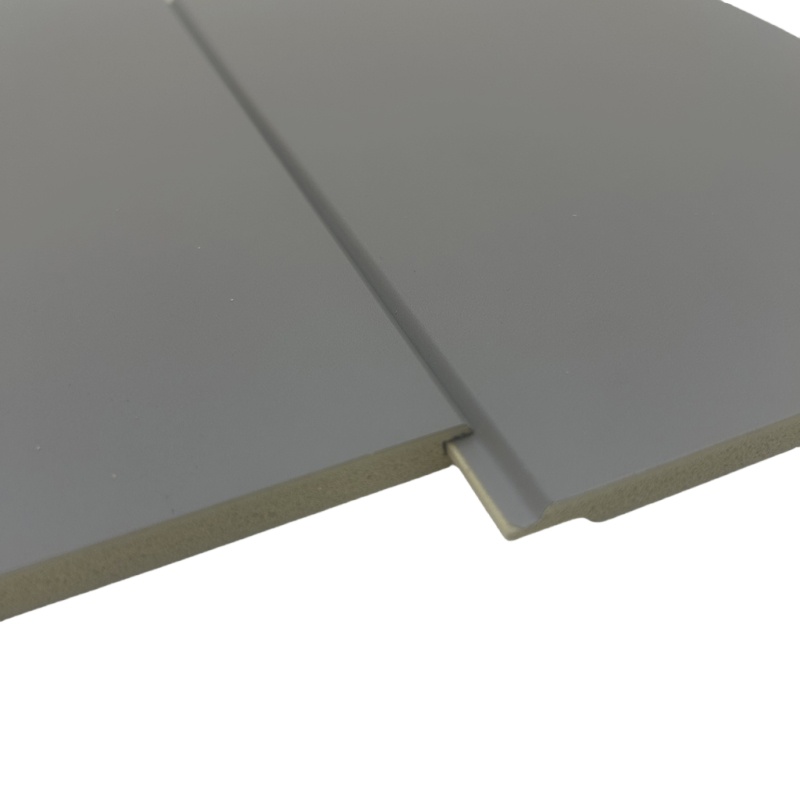

V grooved WPC foam board

product description

Haozhu Factory can customize product thickness, weight, color, etc. according to customer needs.

V-grooved WPC foam board is a very popular grooving method in the current wood veneer panel series. V-grooving not only provides a better aesthetic appearance, but also avoids various deformation problems caused by changes in ambient temperature, thus preventing significant aesthetic damage. Haozhu Decorative Materials Co., Ltd. strongly recommends this grooving method.

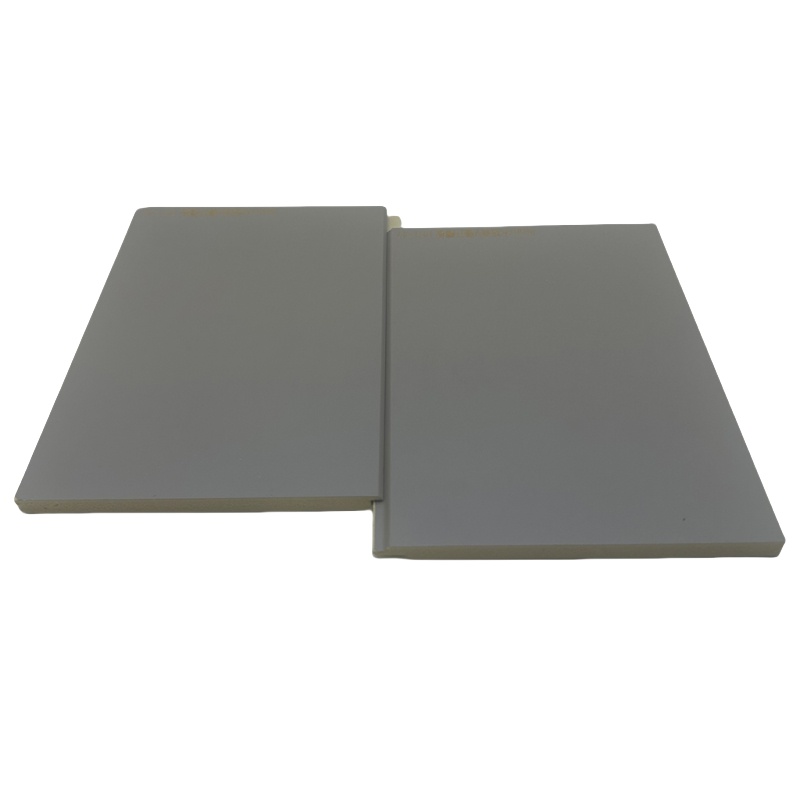

5mm WPC (Wood Plastic Composite) Foam Board is a new-generation building and decoration material made from a mixture of wood fiber, PVC resin, and additives, processed under high temperature and pressure. It combines the natural appearance of wood with the durability and water resistance of plastic, making it an ideal substitute for traditional plywood, MDF, and particle boards.

2. Key Features

✅ Waterproof & Moisture-proof – Suitable for wet environments like kitchens and bathrooms.

✅ Termite & Rot Resistance – No decay, no insects, and long service life.

✅ Eco-friendly – 100% recyclable and formaldehyde-free.

✅ Lightweight but Strong – Easy to cut, screw, and install.

✅ Smooth Surface – Excellent for lamination, painting, or direct printing.

✅ Fire Retardant – Safer than wood in indoor applications.

3. Common Sizes

Thickness: 5mm – 20mm (8mm is standard for interior use)

Width: 1220mm

Length: 2440mm

Density: 0.45–0.8 g/cm³ (customizable)

4. Applications

🏠 Interior Decoration: Wall panels, ceiling boards, and partitions

🚪 Furniture Manufacturing: Cabinets, wardrobes, and shelves

🏢 Advertising Display: Signboards, exhibition panels, and printing sheets

🚿 Construction Use: Door panels, false ceilings, and waterproof boards

5. Processing & Installation

Can be cut, drilled, nailed, or screwed like wood

Compatible with PVC edge banding and lamination

Easy to clean and maintain with simple tools

6. Technical Parameters (Typical 8mm Board)

Property Value Test Standard

Density 0.55–0.65 g/cm³ ASTM D792

Water Absorption < 1% ASTM D570

Flexural Strength > 18 MPa ASTM D790

Fire Rating Class B1 GB 8624-2012

Formaldehyde Emission None EN 717-1

7. Summary

8mm WPC foam board is a multi-purpose, eco-friendly, and cost-effective material ideal for both construction and furniture industries. It is especially popular in interior decoration, bathroom furniture, and marine applications due to its waterproof and termite-proof nature.

product specification

| Product Name | Factory Direct Free Sample Indoor Decorative PVC Coated Cladding Fluted Board Interior Wood Plastic Composite WPC Wall Panel |

| Standard Size | As shown or as your requirement |

| WPC Component | 35% HDPE+60% wood fiber + 5% additives |

| Installation Type | Very easy install with accessories |

| Maintenance | Less maintenance |

| Recycling | 100% recyclable |

| Fire Rating | B1 |

| Free Sample | Send Inquiry for Free Sample!!! |

| Package | Pallet or bulk packing |

| Payment | 30% deposited, the rest should be paid before delivery |

| Delivery time | About 15-20 days for one 20'ctn |

| The differences between wpc and wood materials | |||

| Characteristics | WPC | WOOD | |

| Using Property | Humid Stability | More Stable | will expand after water absorbtion |

| Durability | Long | Short | |

| Termite Resistance | Yes | No | |

| UV Stability | High | Low | |

| Acid and alkali resistance | High | Low | |

| Anti-aging sun | High | Low | |

| Maintenance | Painting | No need | Yes |

| Cleaning | Easy | Middle | |

| Maintenance Cost | No maintenance, low cost | High cost | |

Product advantages

Key benefits of WPC wall panels

WPC panels have many benefits that make them a perfect alternative to traditional wood wall panels. The excellent properties make them even more useful in interior design.

Insulation: The unique design and structure of modern wall paneling give it better thermal and insulating properties. It effectively prevents heat from seeping in and escaping, which helps maintain a more stable indoor temperature.

Sound-absorbing: These soundproof panels can effectively absorb sound and make your indoor environment quieter. It can provide homeowners with a more cozy and quiet living space.

Fire Resistant: Most manufacturers add a flame retardant to WPC panels, making them fire resistant. This can provide extra protection for your home and interior environment.

Durable: WPC wall paneling is more durable than traditional wood wall panels. It can withstand extreme elements and humid environments very well. The superior durability and moisture resistance make it less prone to cracking and rotting.

Easy installation: This paneling is much easier to install and transport. The lighter weight compared to wood panels allows homeowners to even install it themselves.

Low maintenance requirements: wood wall panels require regular maintenance and upkeep as they are used over time. to keep it looking and performing. But WPC wall panels don’t need to worry about such issues at all. All you need to do is to clean it regularly using warm water and cleaners and you are well on your way to ensuring its durability.

exhibition