How to choose a WPC product model

Here’s a clear, practical guide to choosing the right WPC (Wood-Plastic Composite) product model — whether you’re picking decking boards, wall cladding, fencing, or other WPC profiles. WPC products vary widely in structure, performance, and cost, so the right model depends on your application, environment, performance needs, and budget.

Step-by-Step: How to Choose a WPC Product Model

1. Define Your Project & Use Case

Different WPC products are optimized for different applications:

Decking (outdoor floors)

Cladding & Wall Panels

Fencing & Railings

Interior finishes

Each has specific performance and structural expectations. Specifying the exact use helps narrow model choices early on.

SmartBuy

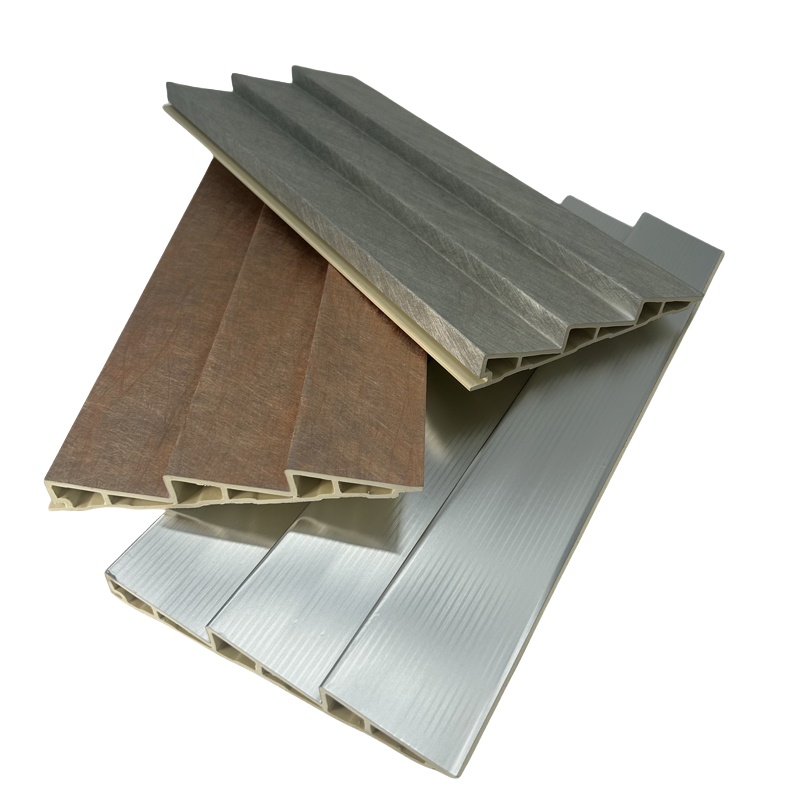

2. Choose the Right Core Type

WPC boards typically come in:

Solid Core — heavier, stronger, better for high-traffic or structural uses.

Hollow Core — lighter and cheaper, but with lower mechanical strength.

Solid boards are preferable when strength and load-bearing matter. Hollow may suit light residential areas.

SmartBuy

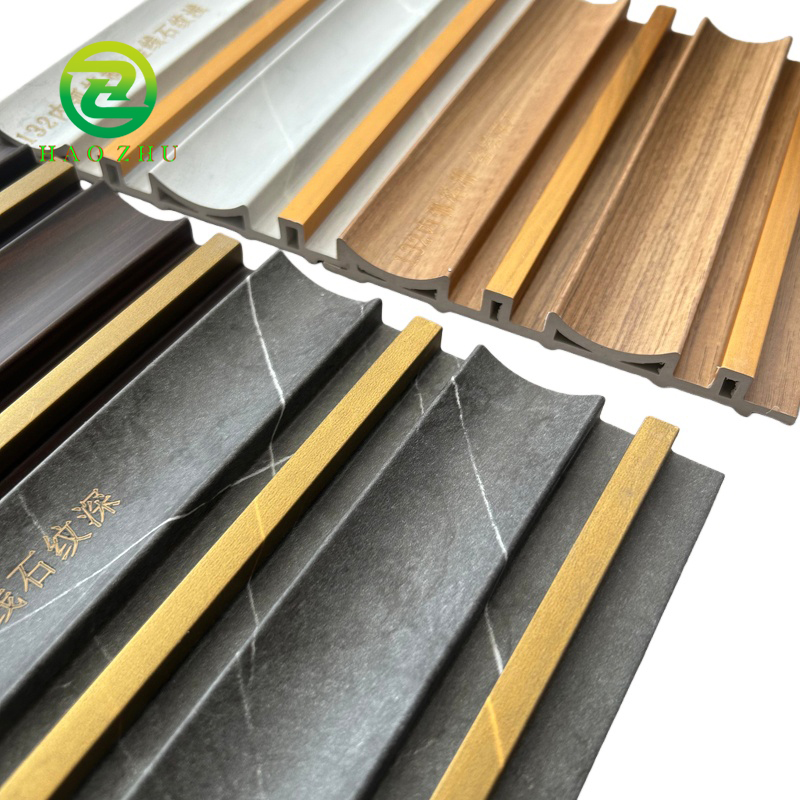

3. Capped vs. Uncapped (Surface Protection)

Capped WPC: Has an extra polymer layer that protects against UV fading, stains, moisture, and wear.

Uncapped WPC: Relies on internal additives; generally cheaper but less durable outdoors.

For areas with strong sun or heavy weather exposure, choose capped WPC for longer life and lower maintenance.

SmartBuy

4. Check Key Performance Specifications

Look at the following technical features when comparing models:

Density & Strength

A higher density (heavier for the same volume) usually means better durability, rigidity, and screw retention.

SmartBuy

Water Absorption & Moisture Resistance

Lower absorption means less swelling, warping, and fungal risk in humid or wet environments.

SmartBuy

UV & Weather Resistance

Vital for outdoor use — confirm UV stabilizers or test data, especially where there’s intense sun exposure.

SmartBuy

Slip Resistance (for Decking)

Textured or grooved surfaces improve safety and traction when wet.

SmartBuy

Thermal Expansion

WPC expands/contracts with temperature; certified models or engineered locking systems help mitigate warping.

SmartBuy

5. Material Composition & Additives

Ask the supplier about:

Wood/plastic ratio — affects strength and appearance.

Additives such as UV inhibitors, coupling agents (better bonding), and anti-mold agents.

Different compositions suit different climates and aesthetic preferences.

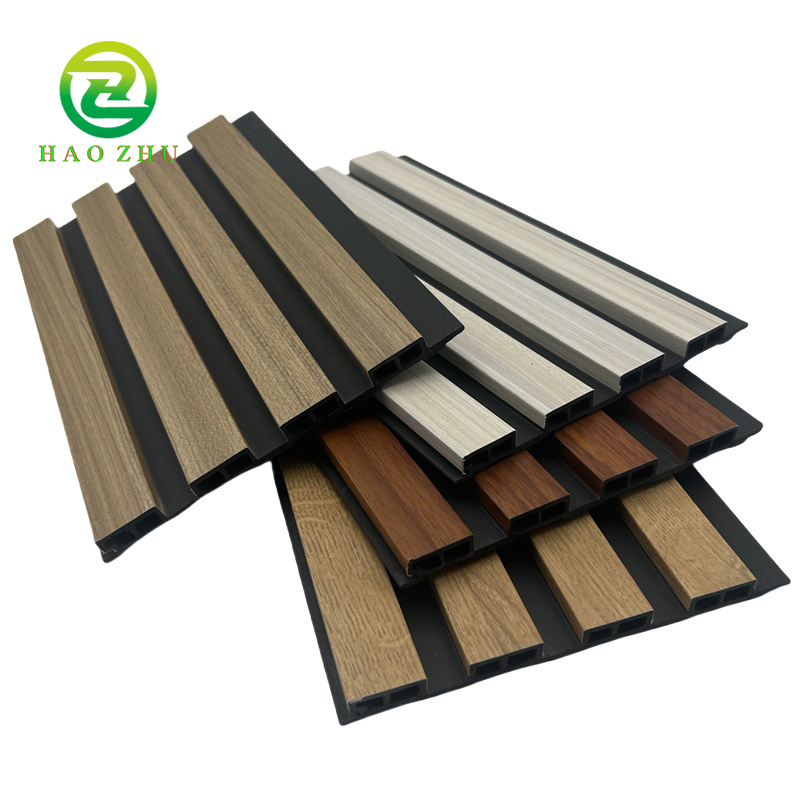

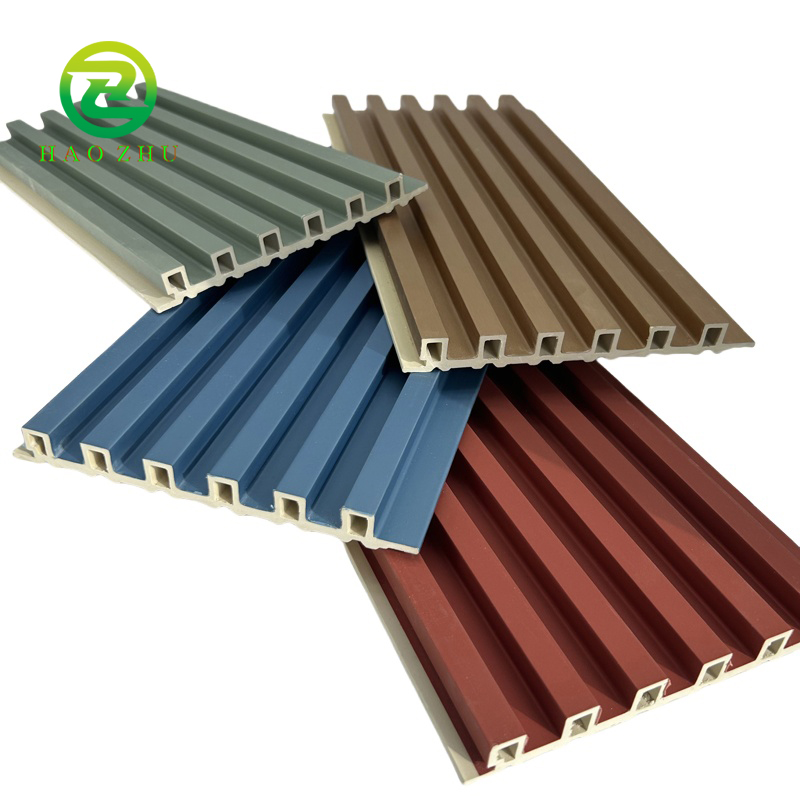

6. Aesthetics & Surface Finish

Surface texture, color, and embossing can change the look significantly:

Realistic wood grain

Matte vs. glossy finish

Deep embossing for texture and slip control

View physical samples if possible — colors often look different in person than online.

SmartBuy

7. Installation Compatibility

Consider the installation method the model supports:

Hidden fasteners / clip systems

Tongue-and-groove

Nail-down or adhesive systems

Choose a model that fits your skill level and structural setup.

SmartBuy

8. Warranty & Certifications

Longer, clear warranties (e.g., 10–25+ years) often indicate product confidence.

Certifications (ASTM, ISO, FSC, local building codes) ensure quality, safety, and environmental standards.

SmartBuy

+1

9. Consider Climate & Environment

Your local climate matters:

Hot, sunny regions → strong UV resistance and capped boards

Rainy, high-humidity regions → low water absorption and anti-mold properties

Match the model’s tested performance to your environment.

SmartBuy

10. Balance Price vs. Long-Term Value

Cheap models might save money upfront but can cost more over time due to:

Fading

Warping

Frequent replacement

Investing in mid-to-premium products often offers better lifecycle performance and lower maintenance costs