The development history of WPC wall panel

1. Early origins (1900s–1960s)

The idea of combining wood fibers with plastics dates back to the early 20th century.

Early experiments focused on improving dimensional stability and moisture resistance of wood.

Limited success at first due to poor bonding between wood and plastic and weak processing technology.

2. Industrial experimentation (1970s–1980s)

Advances in polymer chemistry (especially polyethylene and polypropylene) made WPC more feasible.

Researchers began using wood flour as a filler in thermoplastics.

Main applications were automotive parts and industrial panels, not construction.

Environmental awareness and oil crises increased interest in using recycled materials.

3. Commercial breakthrough (1990s)

Major progress came with coupling agents (like maleic anhydride), which improved bonding between wood fibers and plastic.

WPCs began to be mass-produced for outdoor decking in North America.

Key advantages over natural wood:

Better resistance to rot and insects

Lower maintenance

Use of recycled plastics and wood waste

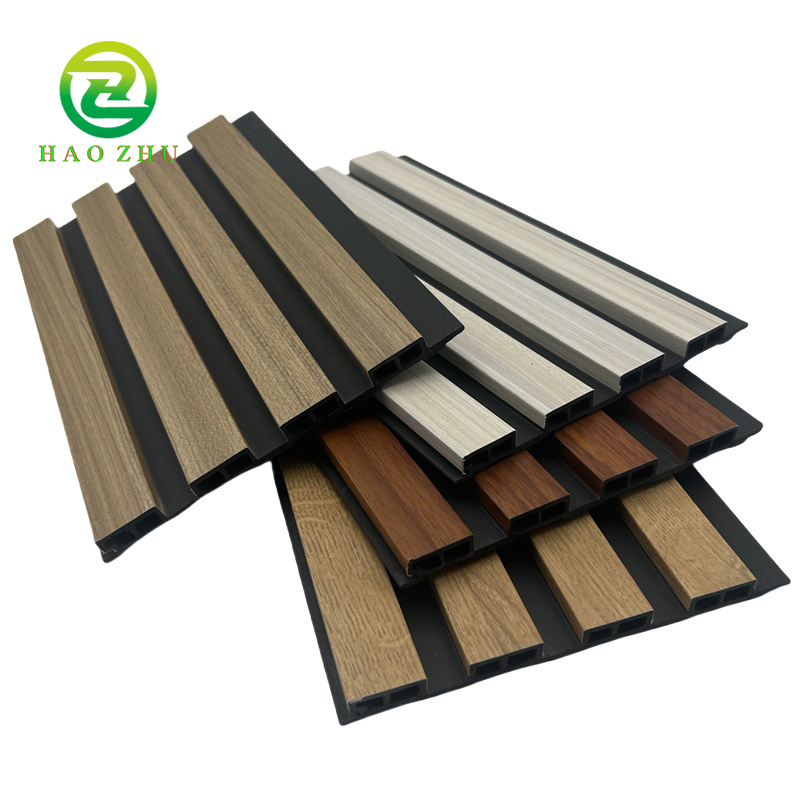

4. Rapid market expansion (2000s)

WPC products expanded into:

Decking

Fencing

Cladding

Railings

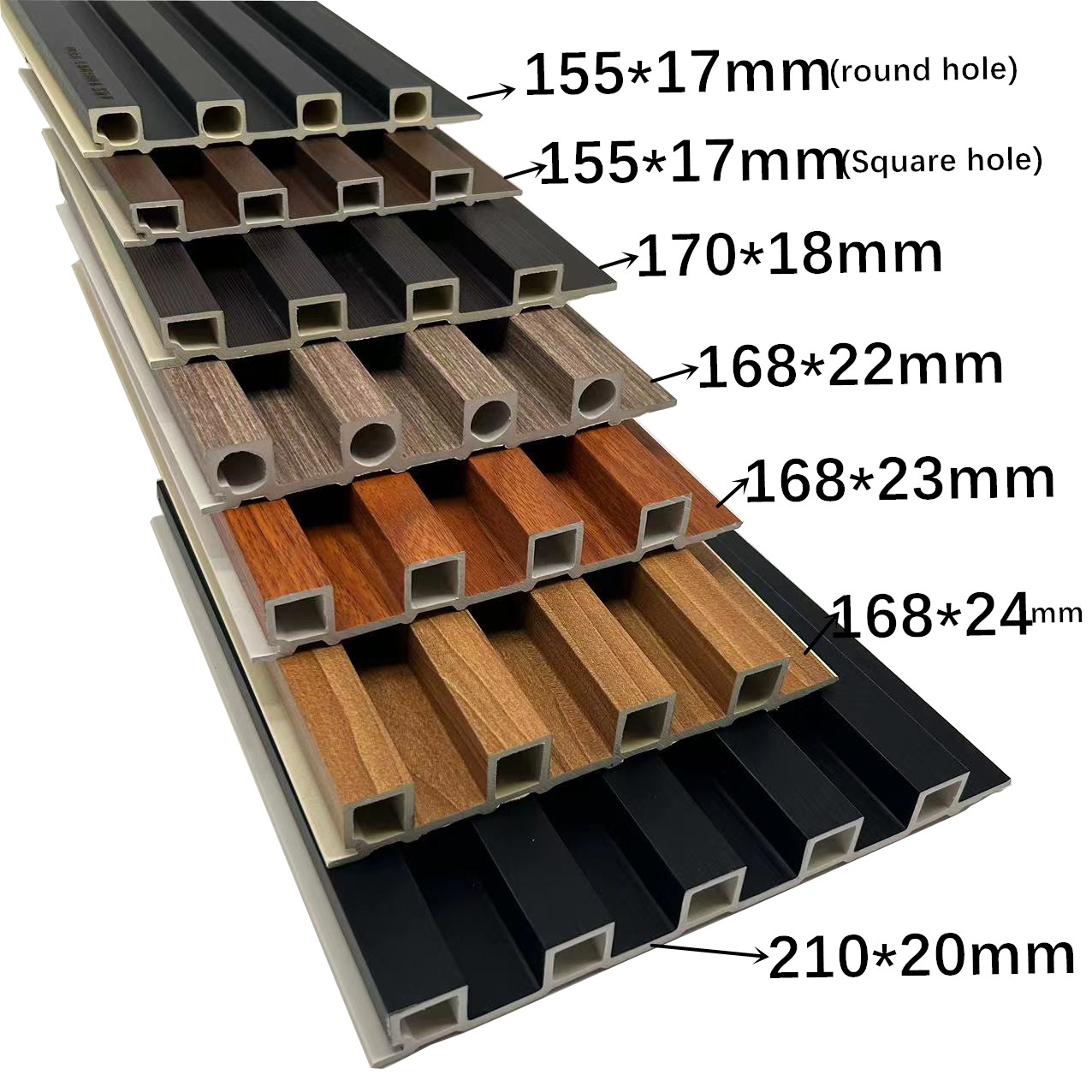

Manufacturing techniques such as extrusion and injection molding matured.

Europe and Asia (especially China) became major producers.

Standards and testing methods for WPC performance were established.

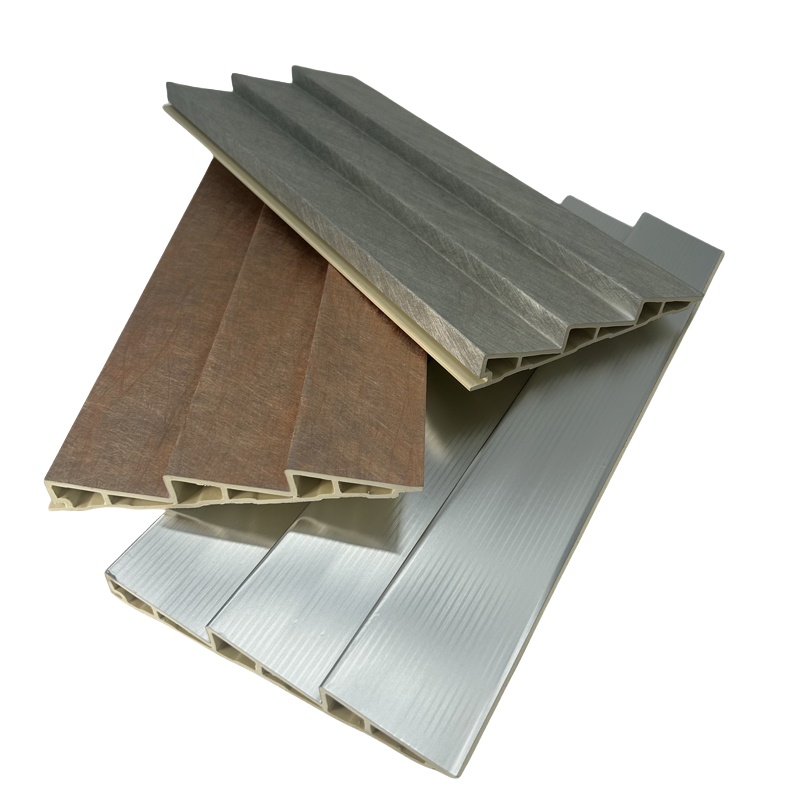

5. Technological refinement (2010s)

Focus shifted to:

Improved surface textures (more wood-like appearance)

Enhanced UV resistance and color stability

Better fire resistance and mechanical strength

Co-extrusion technology introduced protective outer layers.

WPC became common in green building and landscape architecture.

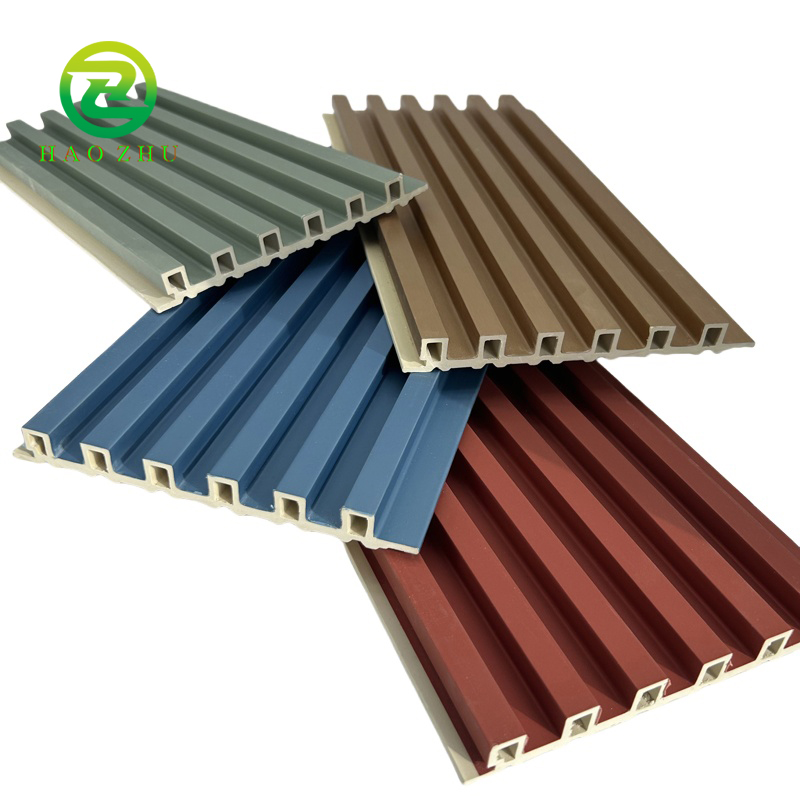

6. Current trends (2020s–present)

Emphasis on sustainability and circular economy:

Higher recycled content

Bio-based plastics

Smart and high-performance WPCs with:

Anti-slip surfaces

Improved recyclability

Growing use in infrastructure, modular buildings, and urban furniture.