Introduction to Wood-Plastic Sound Absorbing Panels

Introduction to Wood-Plastic Sound Absorbing Panels

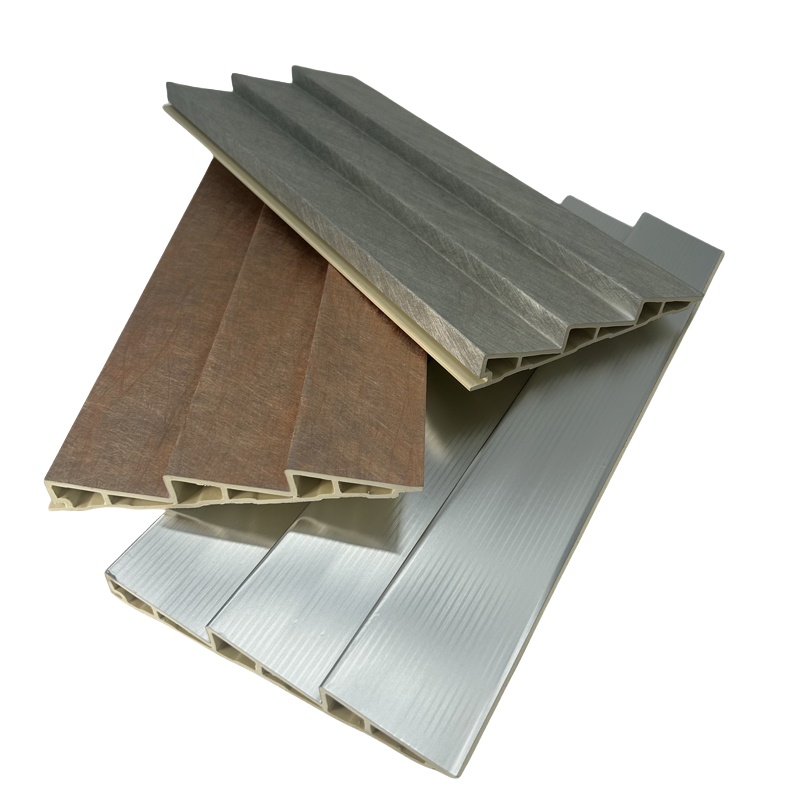

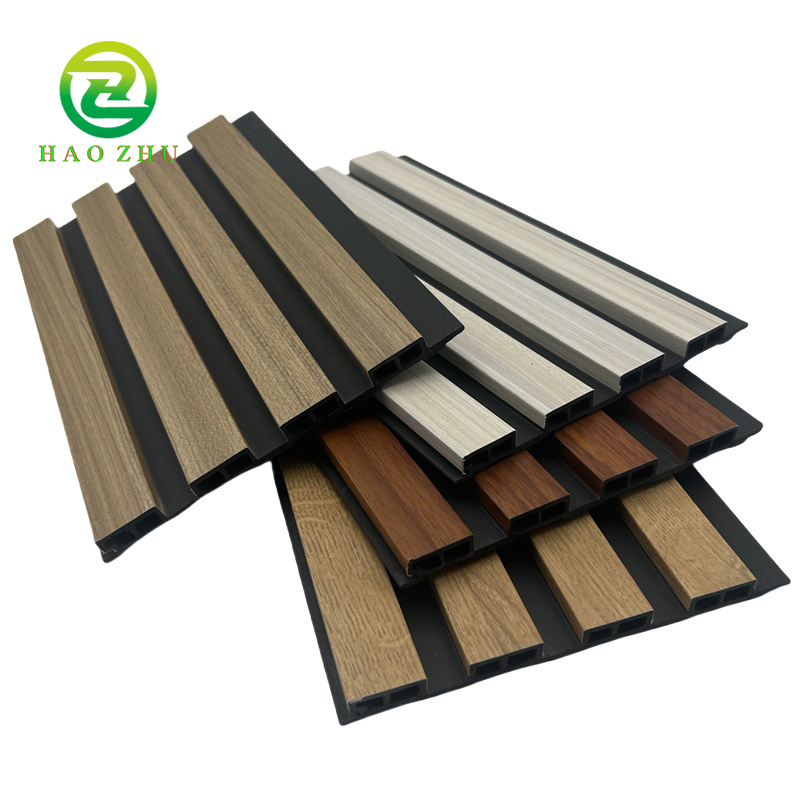

Wood-plastic sound absorbing panels are innovative acoustic materials that combine wood fibers with thermoplastic polymers to create panels that offer both sound absorption and decorative appeal. By integrating natural wood texture with modern polymer technology, these panels deliver acoustic performance while maintaining durability, moisture resistance, and aesthetic flexibility.

Material Composition

Wood-plastic sound absorbing panels are typically made from:

Natural wood powder or fibers

Plastic materials such as PVC, PE, or PP

Additives for UV resistance, fire retardancy, and structural stability

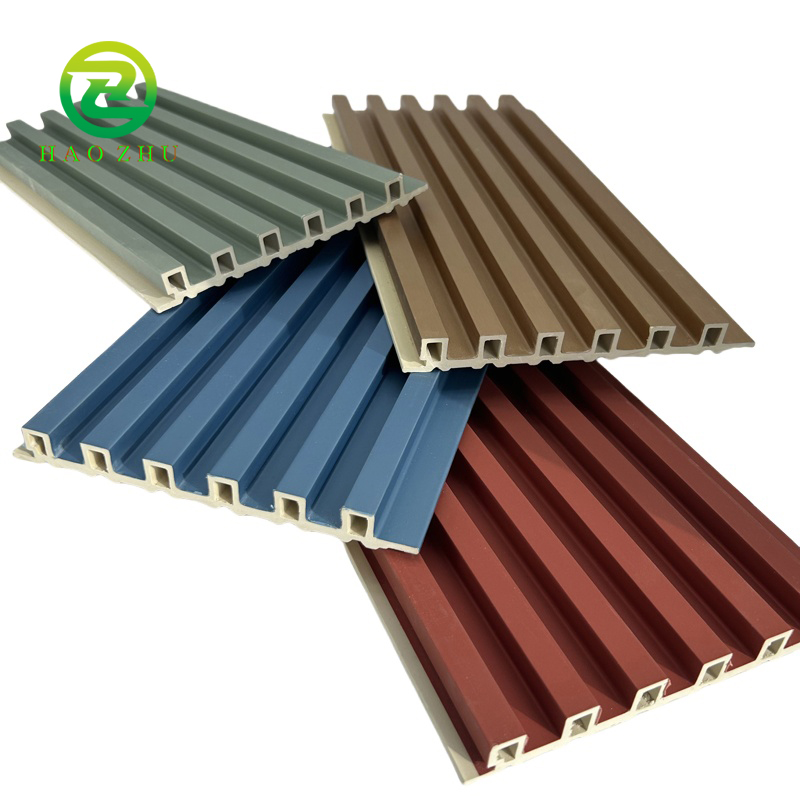

The panels often feature perforated surfaces, slotted designs, or porous cores, which enhance their ability to absorb sound waves and reduce noise reflection.

Acoustic Performance

These panels are designed to:

Reduce reverberation and echo

Improve speech clarity

Absorb mid- and high-frequency noise

They are commonly used in environments where acoustic comfort is important, such as offices, conference rooms, theaters, schools, hotels, and commercial interiors.

Key Advantages

Effective sound absorption with stable acoustic performance

Moisture-resistant and mold-resistant, suitable for humid environments

Durable and low-maintenance compared to traditional wood panels

Eco-friendly, often incorporating recycled materials

Aesthetic versatility, available in various colors, textures, and finishes

Applications

Wood-plastic sound absorbing panels are widely applied in:

Commercial and office buildings

Public spaces and transportation hubs

Residential interiors

Recording studios and performance venues

Conclusion

By combining functional acoustics with modern design and environmental benefits, wood-plastic sound absorbing panels provide a practical and visually appealing solution for contemporary architectural and interior acoustic needs.