How to distinguish the quality of WPC?

WPC (Wood–Plastic Composite) quality can be judged by looking at materials, structure, performance, and manufacturing details. Here’s a practical, step-by-step way to distinguish high-quality vs low-quality WPC, whether for decking, panels, doors, or boards.

1. Check Raw Materials (Most Important)

✔ High-quality WPC

Uses virgin HDPE or PP (not recycled mixed plastics)

Wood fiber/flour is fine, dry, and uniform

Contains UV stabilizers, anti-oxidants, and coupling agents

✘ Low-quality WPC

Made with mixed recycled plastics (smells bad when cut)

Wood powder contains impurities or moisture

Lacks additives → fades, cracks, or becomes brittle

🔍 Tip: Ask for a material composition sheet or test report.

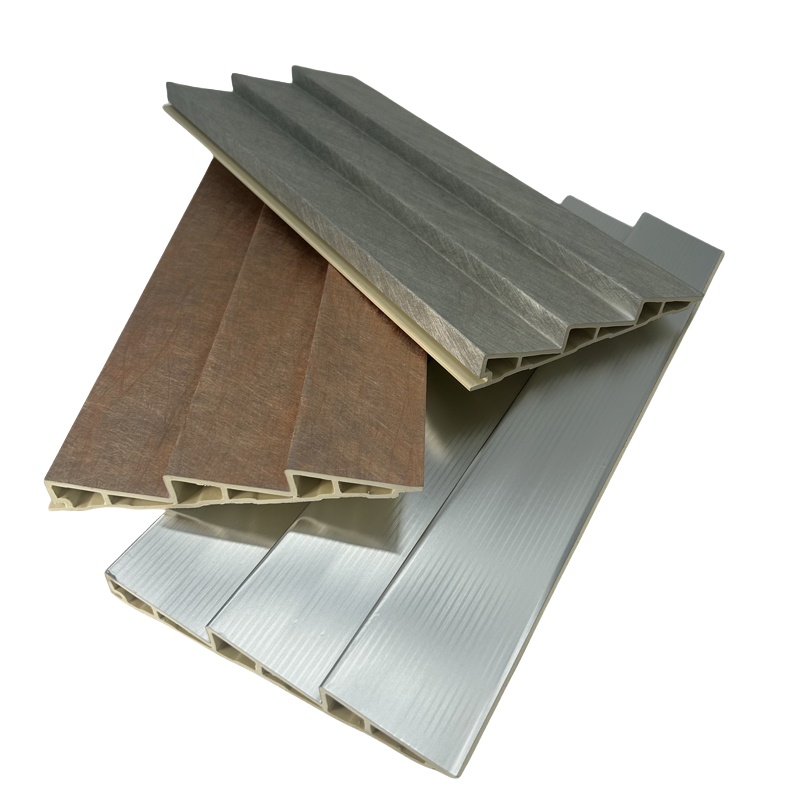

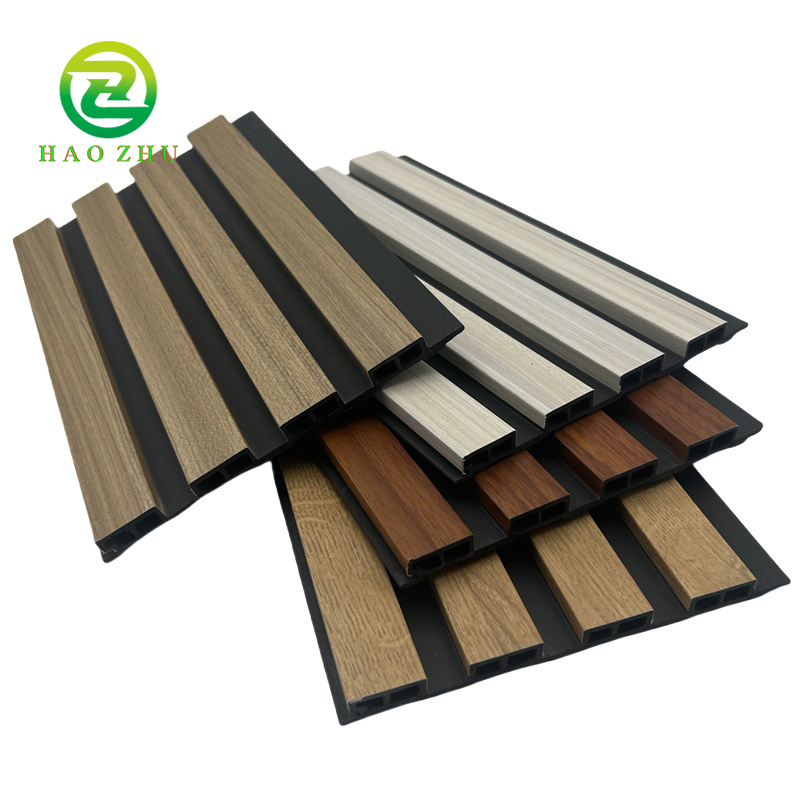

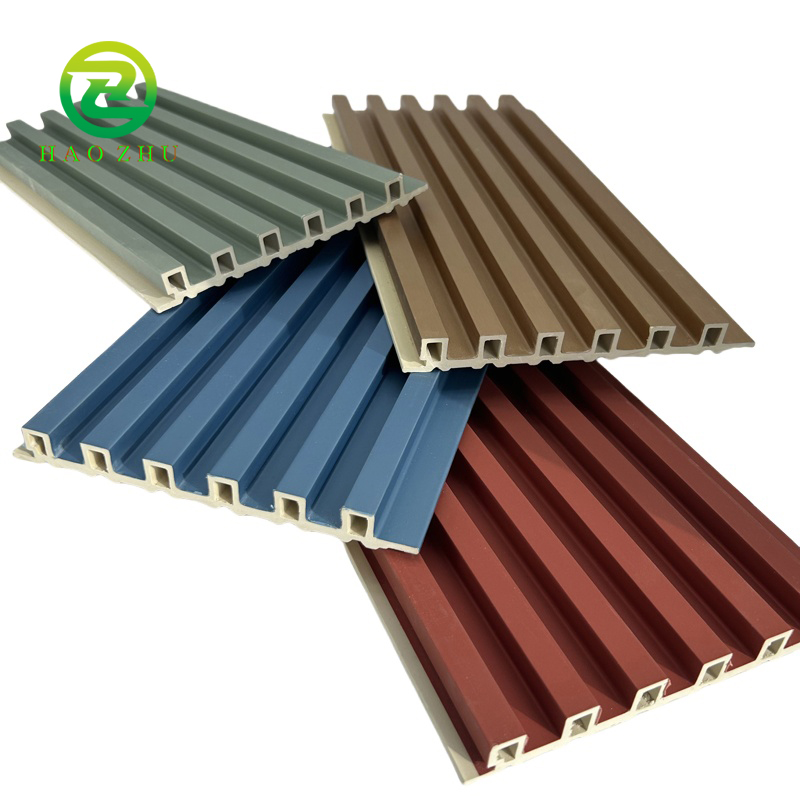

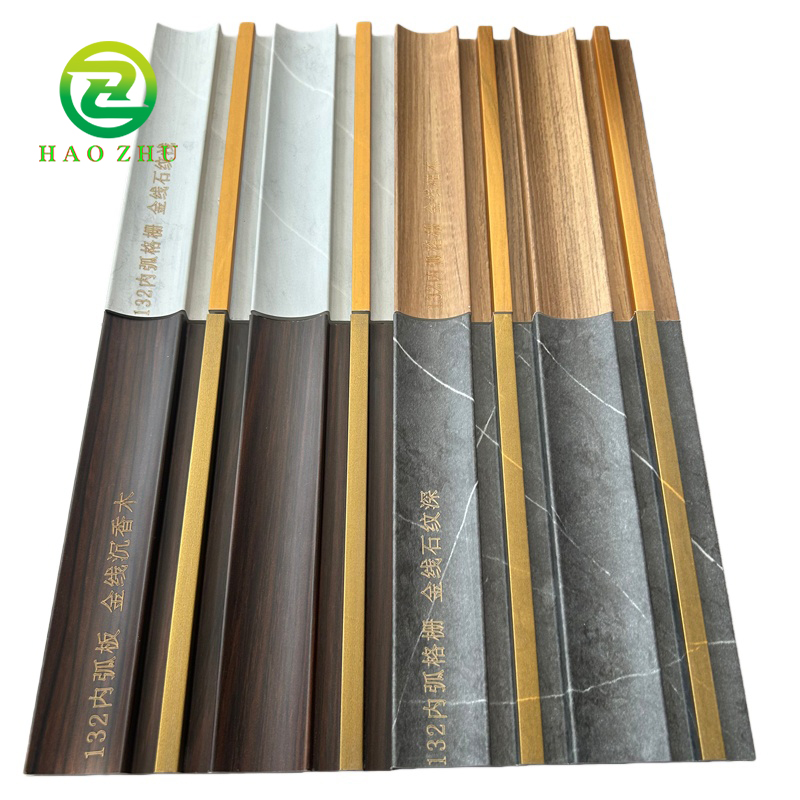

2. Look at Surface & Color

✔ High-quality

Smooth or evenly textured surface

Uniform color throughout

No visible white spots, bubbles, or streaks

✘ Low-quality

Patchy color

Rough, chalky surface

Visible pores or pinholes

🔨 Scratch test: Scratch lightly—good WPC won’t show white plastic underneath.

3. Density & Weight

Higher density = better strength

Light boards often mean too much plastic or fillers

📏 Typical good WPC density:

1.25–1.4 g/cm³ (varies by application)

4. Strength & Flexibility Test

✔ High-quality

Slight flexibility without cracking

Returns to shape after bending

Holds screws firmly

✘ Low-quality

Cracks when bent

Brittle edges

Screws loosen easily

🧪 Simple test: Press or bend a sample—listen for cracking sounds.

5. Water Resistance Test

Immerse a piece in water for 24–48 hours

✔ Good WPC

Minimal swelling (<1%)

No delamination

No surface whitening

✘ Poor WPC

Swells noticeably

Surface becomes rough or soft

6. Fire & Heat Resistance

High-quality WPC:

Self-extinguishing

No dripping molten plastic

Poor WPC:

Burns fast

Strong plastic odor

🔥 Ask for fire-retardant grade if used indoors.

7. UV & Weather Resistance (Outdoor Use)

✔ Good WPC

Color fading ≤ 5–8% after 1000–2000 hours UV test

No surface cracking

✘ Poor WPC

Fades quickly

Becomes brittle within 1–2 years

📄 Request UV aging test reports (ASTM G154 / EN standards).

8. Manufacturing Process

✔ High-quality

Extruded under controlled temperature

Co-extrusion (protective outer layer) for outdoor products

Clean, precise cuts

✘ Low-quality

Inconsistent thickness

Rough edges

Voids inside the profile

9. Smell Test

Good WPC → no strong smell

Bad WPC → burnt plastic or chemical odor

10. Certifications & Warranty

Look for:

ISO 9001

CE / ASTM / EN standards

5–15 year warranty (outdoor WPC)